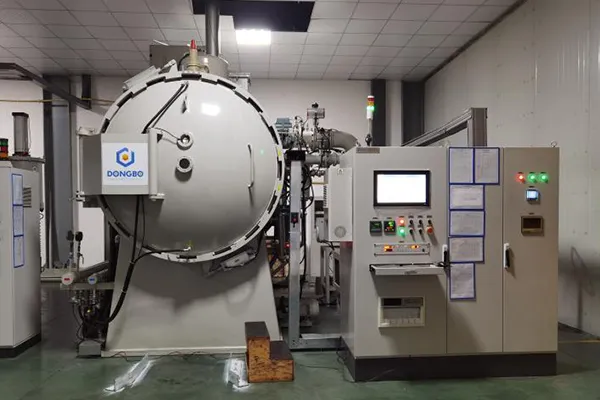

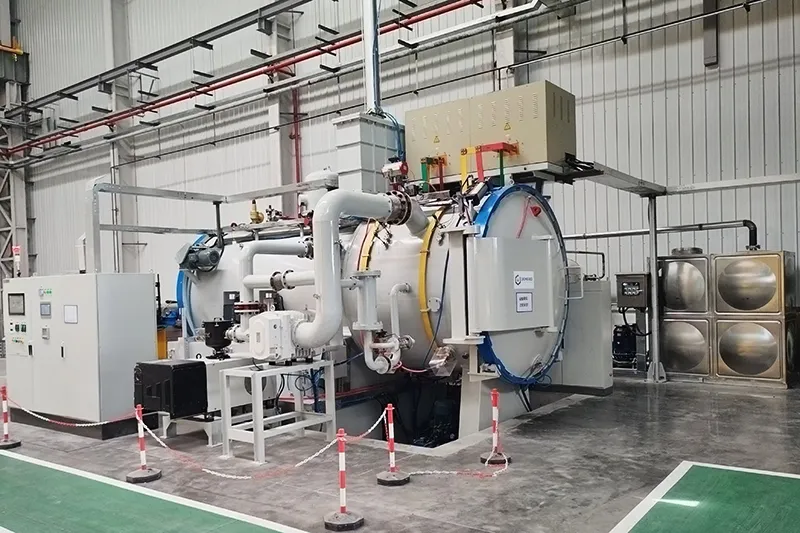

Ensuring the durability of aerospace engine bearings isn’t a simple task. These components must handle high rotational speeds, extreme temperatures, and continuous mechanical stress. Any weakness in material properties can lead to performance degradation or even failure. Hence, Harbin Bearing Group Co., Ltd. and Xinchang Jingyi Bearing Co., Ltd. chose our low pressure vacuum carburizing furnace to refine their heat treatment process.

Rather than relying on a single treatment step, the process combined vacuum carburizing, spheroidizing annealing, double quenching, cryogenic treatment, and tempering. Each stage was carefully controlled to ensure the right balance between hardness, wear resistance, and core toughness. Main parameters included a carburizing temperature of 930°C, a carbon potential of 1.0 wt% C, and a target case depth of 1.0 mm. For martensitic stainless steel (such as 15Cr14Co12Mo5Ni), achieving a uniform and well-formed carburized layer is particularly challenging. However, with this furnace, the case depth exceeded 0.92 mm, and the surface hardness reached 65 HRC, surpassing conventional industry benchmarks. The bearings underwent rigorous testing, including prolonged high-speed rotation and thermal cycling, demonstrating improved dimensional stability and fatigue resistance under demanding aerospace conditions.

This project showcased the versatility and precision of our vacuum carburizing technology. By refining the heat treatment process, both manufacturers achieved longer-lasting, high-performance bearings, ensuring greater reliability for aerospace applications.