Industry Applications of Vacuum Heat Treatment Furnaces

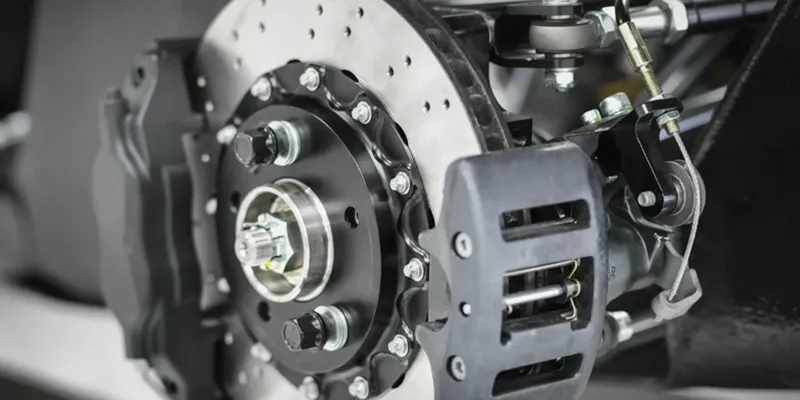

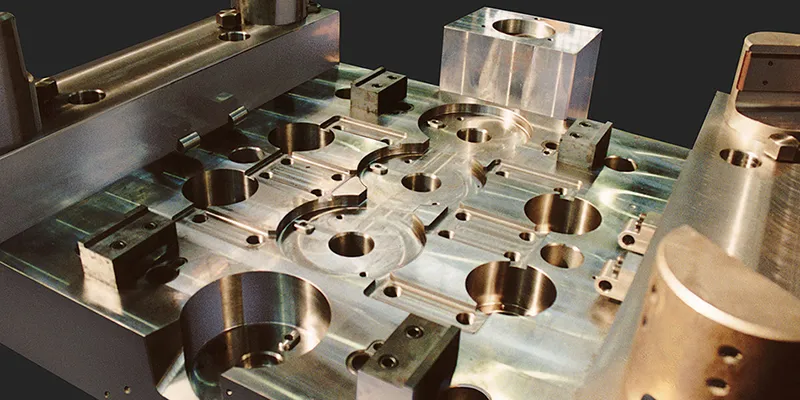

Vacuum heat treatment is widely used in construction machinery to improve the strength, wear resistance, and durability of key components. This process enhances the performance of gears, bearings, shafts, and other load-bearing parts in heavy equipment, ensuring reliable operation under demanding conditions.

Applications

- Gears, bearings, and shafts undergo heat treatment to increase hardness, reducing wear and extending their lifespan.

- Processing in a vacuum environment prevents oxidation and decarburization, preserving material integrity and mechanical properties.

- Controlled heating and cooling cycles ensure precise hardness distribution, improving durability under heavy loads.

- Optimized energy consumption enhances production efficiency while minimizing material waste.

- Excavators, loaders, cranes, and bulldozers benefit from vacuum heat treatment, ensuring reliable performance in demanding conditions.

Case Studies

High Temperature Carburizing Furnace for Transmission Gear

Traditional carburizing methods can be slow and inefficient, especially for large locomotive transmission gears that require deep surface hardening. Tianjin Teek Transmission Co., Ltd. was facing two major issues: long processing times and surface oxidation, both of which increased production costs and affected final product quality.

See MoreVacuum Carburizing and Carbonitriding Furnace for Precision Parts

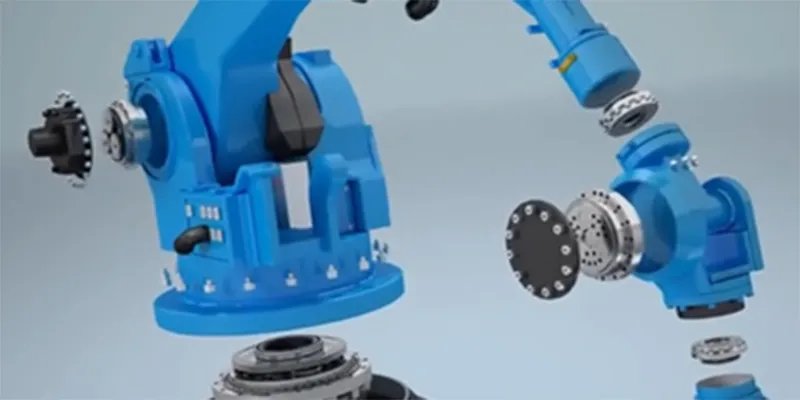

Precision parts manufacturing demands strict material performance, especially for components exposed to constant friction, heavy loads, and repetitive motion. Zhejiang Xunaye Precision Manufacturing Co., Ltd. and Nantong Jucheng Electromechanical Manufacturing Co., Ltd. needed a reliable heat treatment process to ensure their parts met high durability and performance standards. To address this, we supplied a vacuum carburizing and carbonitriding furnace tailored for robotic joints, automotive transmission systems, and power tool components.

See MoreRecommended Products

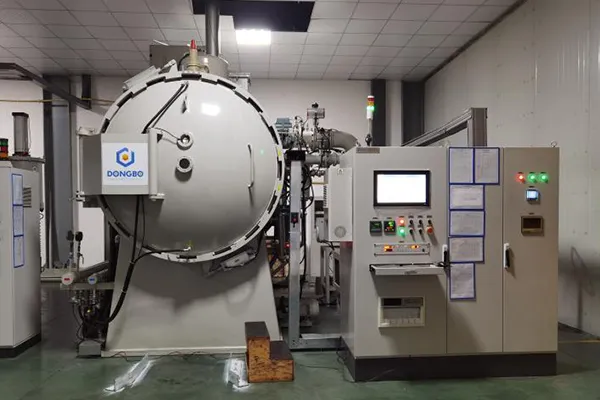

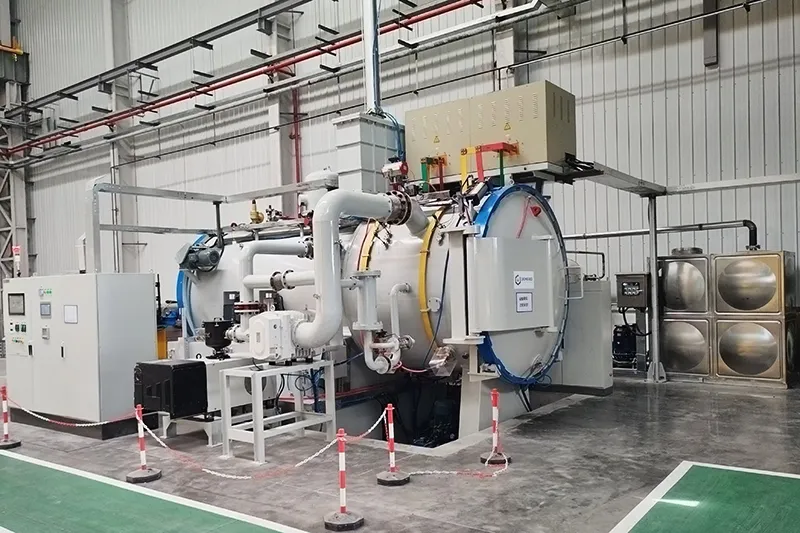

Vacuum Heat Treatment Line

The vacuum heat treatment line integrates multiple heat treatment processes, such as quenching, tempering, and carburizing. It enables automated and intelligent manufacturing, meeting the diverse requirements of construction machinery components. This type of heat treatment line can be customized based on user needs to optimize the manufacturing process.

-

- Vacuum Sintering Furnace

- Max. load capacity (kg): 200-1200

- Max. temperature (℃): 1600

-

- Vacuum Brazing Furnace

- Max. load capacity (kg): 1000-3000

- Max. temperature (℃): 700

-

- Vacuum Annealing Furnace

- Max. load capacity (kg): 800-5000

- Max. temperature (℃): 1200

Start Your Project with Us Today!

- Email: James.lu@dongboth.com

- Tel.: +86-24-81051555