Industry Applications of Vacuum Heat Treatment Furnaces

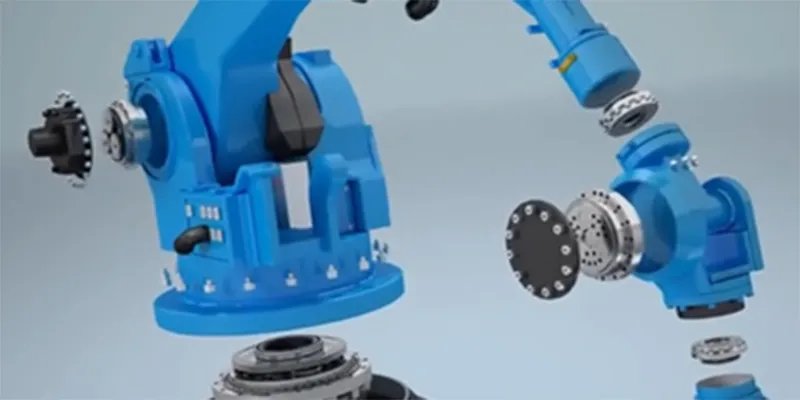

In rail transport, many components, such as diesel engine connecting rods and crankshafts, are subjected to high loads. Utilizing low-pressure vacuum carburizing and carbonitriding processes significantly improves their wear resistance and fatigue strength, ensuring reliable performance under demanding conditions.

Our low-pressure vacuum carburizing (carbonitriding) furnaces ensure oxidation-free surfaces, superior surface quality, and minimal deformation, with excellent process stability and repeatability. The treated parts offer outstanding overall performance and extended service life. These furnaces also feature pollution-free operation, low energy consumption, reduced production costs, and a high degree of automation, making them highly effective in the railway industry.

Case Studies

Dongbo developed a low-pressure vacuum carburizing furnace for Jilin Ande Electrification Technology Co., Ltd. to improve the performance of retaining rings and snap rings. These components need to maintain a balance between surface hardness and core toughness to ensure durability under demanding conditions.

To meet these requirements, we applied a pulse-based carburizing process designed specifically for high-grade stainless steel retaining rings. This heat treatment method enhances wear resistance while maintaining structural integrity. Testing confirmed that the treated rings had precise dimensions, reduced weight, and improved mechanical properties, ensuring reliable long-term use.

Recommended Products

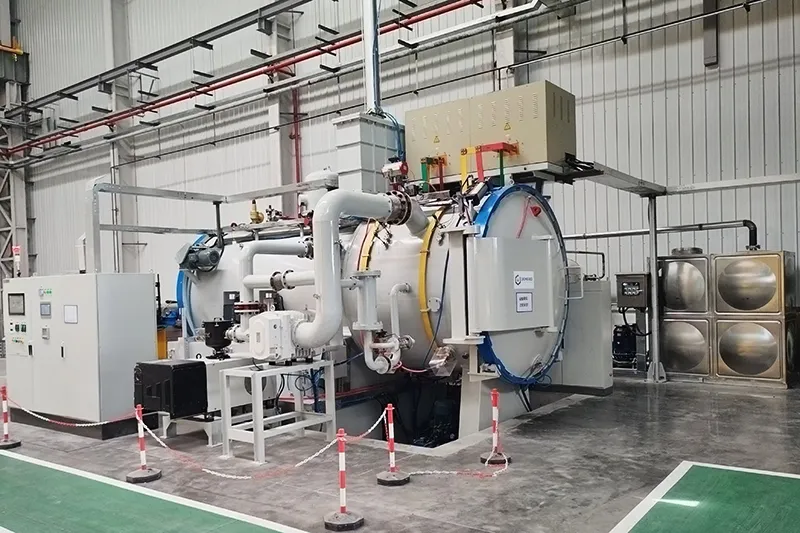

Vacuum Heat Treatment Line

The vacuum heat treatment line integrates multiple heat treatment processes, including vacuum low-pressure carburizing, oil quenching, high-pressure gas quenching, tempering, and cleaning. It enables the efficient, flexible, precise, and clean production of key components in the rail transport industry. Equipped with an intelligent control system, this heat treatment line enhances process efficiency and ensures consistent product quality, meeting the rigorous demands of modern rail transport manufacturing.

-

- Vacuum Sintering Furnace

- Max. load capacity (kg): 200-1200

- Max. temperature (℃): 1600

-

- Vacuum Brazing Furnace

- Max. load capacity (kg): 1000-3000

- Max. temperature (℃): 700

-

- Vacuum Annealing Furnace

- Max. load capacity (kg): 800-5000

- Max. temperature (℃): 1200

Start Your Project with Us Today!

- Email: James.lu@dongboth.com

- Tel.: +86-24-81051555