Vacuum Heat Treatment Furnace

Vacuum Brazing Furnace

Vacuum Heat Treatment Furnace

Vacuum Brazing Furnace

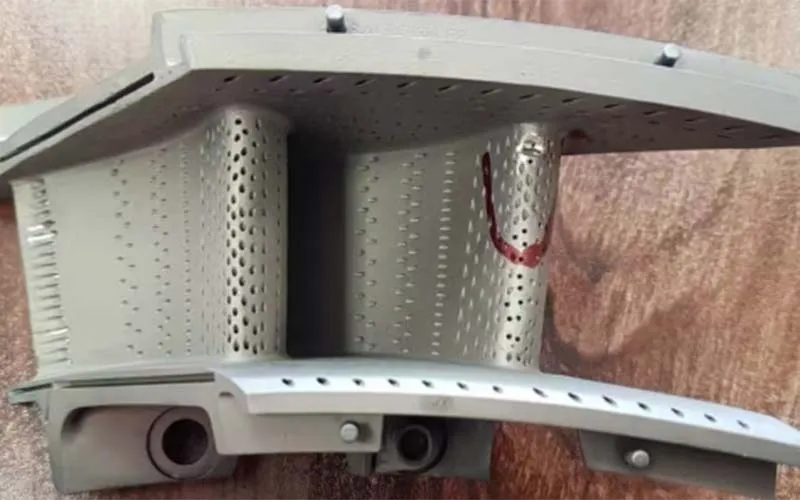

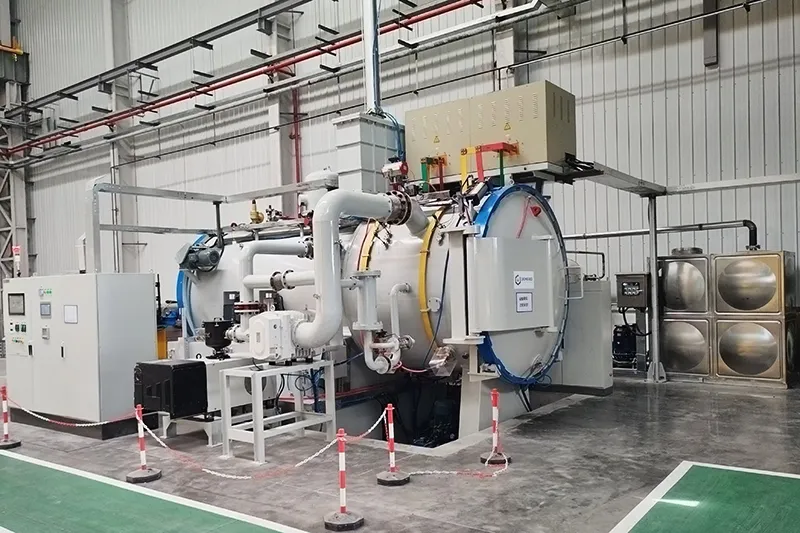

Our vacuum brazing furnace enables high-precision welding of components in a vacuum or inert gas-protected environment, enhancing corrosion resistance, reducing processing steps, and lowering overall production costs.

This advanced brazing method is ideal for industries with stringent quality demands, such as aerospace, nuclear energy, and automotive manufacturing. Traditional manual or machine welding methods often fall short of meeting the exacting requirements of these sectors. Vacuum brazing ensures stronger, cleaner, and more precise welds, making it an essential solution for high-precision industrial applications. The heat treatment furnace supports brazing of various materials, including aluminum and aluminum alloys, copper and copper alloys, stainless steel, alloy steels, low-carbon steel, titanium, nickel and nickel alloys (such as Inconel). Among these, aluminum and aluminum alloys are the most widely used in vacuum brazing applications. The selection of materials is determined based on the specific requirements of the brazing process, ensuring optimal results for each application.